We’ve been farming at Woodhorn Farm since 1882 and during that time there have been some key milestones. Some of these came from technical advances, some were driven by the need for diversification, but some were key decisions about the direction we wanted to take the business in and the role we have as custodians of the land.

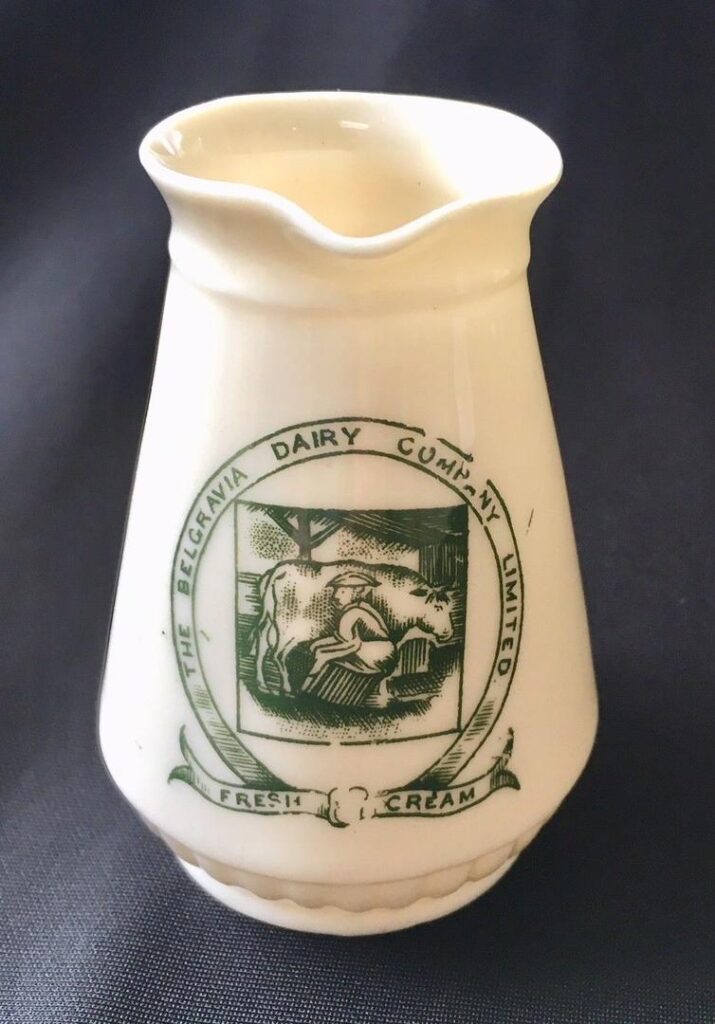

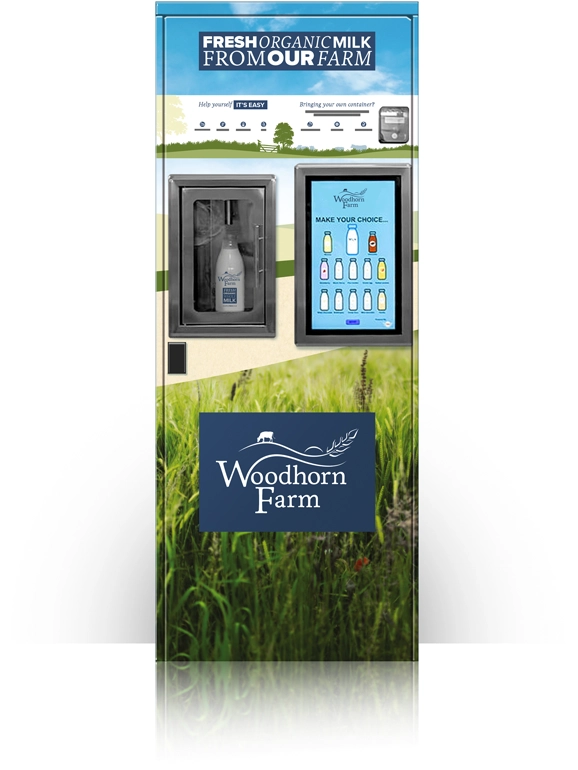

Probably the biggest decision was the move to becoming a fully organic farming operation in 1998. Looking back there’s little else that would have such a fundamental impact on the way we operate as a business – even Brexit. So whilst we continue to diversify, like with the launch of our milk vending operation recently, and continue to reach key milestones in our business growth, the decision John Pitts took 25 years ago was a significant one and dictates almost everything else we do today. As a result the markets we now sell into are more limited than if we weren’t organic and we have to achieve a slight premium to cover the increased costs of production. On the flip side, the success of our milk vending operation is in part due to the benefit of being able to offer organic whole milk direct from the dairy – rather than just fresh milk.

The other consideration in choosing to farm organically is that it’s not an overnight process. It’s certainly not as simple as wanting to become organic tomorrow! Our farm, like many others, had been farmed traditionally for generations with an impact on the soil quality that needed to work its way through. Today we’ve developed ways of working and our own supply chains of fertiliser and humus that support us in being organic, but these didn’t exist on day one. So, we had to work through a transition period, set up new relationships and fundamentally alter our way of working and thinking! And this is a key point. Organic is not just a way of working – it’s also a thought process and a way of life.

Protecting and encouraging wildlife

From a farming perspective organic means farming in a way that protects and encourages wildlife whilst looking after the health of the soil. So, instead of relying on chemicals, we strive to work with nature to feed the soil and control pests. We use crop rotations, legumes, clover and vetches along with our own composted cow manure to build fertility in the soil.

There are plenty of benefits of organic farming, though most people think of the absence of pesticide and/or antibiotic residues first. For us it is also about the environment as a whole; by not using pesticides we’ve seen a transformation of the flora and fauna on the farm. No herbicide usage means that all our crops have varying levels of weeds and wildflowers in them. These act as a habitat for a wide range of insects, small mammals and ground living birds.

Animal welfare

Where animals are concerned, organic is about maximising their welfare, concentrating on the principle of prevention rather than cure. Organic means free-range and all our animals are grazed on fresh grass throughout the spring, summer and autumn period and fed home grown forage through the winter. All our feeds are, of course, GM free. We proudly antibiotic free across the herd now, with herbal and homeopathic remedies the preferred options for dealing with health related issues.

We’re not leaving it there

Once we’d made the decision to become an organic farming operation, there’s little else that can be changed in agricultural terms that has as big an impact. There are no ‘levels’ when it comes to organic and it’s impossible to become more organic…! So, anything we do now concerns better land management and increasing the positive impact of our work on the soil, wildlife and our animals. Here’s what we’re planning or already underway:

Land management – we now have a zero bare soil policy. This means there is always something in the ground, so as we finish cropping and harvesting, we immediately replant with a different crop or natural green fertiliser. Rather than being classed as intensive farming, this process is referred to as a ‘green bridge’ helping hold nutrients in the soil, limiting erosion and reducing run off into rivers and ditches.

Land management – we’re working towards minimum tillage. Each time the soil is disturbed, nutrients escape and the structure is broken down a little more. This also releases carbon that would otherwise be sequestered in the soil. Ploughing and tilling the fields can have a detrimental impact on soil health as well as releasing carbon into the atmosphere. We’re therefore looking at how we can minimise surface and ground disturbance. It is a bit of a trade off as to use our own green fertilisers (vetch, legumes, clover etc.) to maximum effect, they need to be ploughed back into the ground to encourage them to break down and release nutrients at root level. At present, we plough ahead of our main crops, but our cover crops and fertilisers are drilled directly into the soil. It’s an area whereby there is currently a lot of research and innovation taking place and so we’ll continue to adapt as soon as we can.

A bold move that has paid off

Back in 1998, John’s decision was still something of a bold move. Other farmers were moving to partial organic farming but John felt it needed to become a wholesale change across the entire farm. Today our organic farming activities extend to 1,500 acres on the Chichester Plain and the South Downs. We have a 250 head of organic dairy cows and sell our milk, some 5,000+ litres a day, through our organic co-operative, Organic Herd, and directly to the public via our Woodhorn Farm milk vending machines. Our crops go to organic producers manufacturing a range of foods and drinks, like our barley which is used by a European organic brewery.

We understand what it takes to be an organic farm and actively embrace it. We also have plans to do more. It’s not necessarily been easy; organic farms are often more at the mercy of nature than non-organic farms and major diseases or extremes of weather can, and have, impacted us more than other farmers over the years. But organic remains a philosophy we’re committed to, ultimately we believe that how we farm matters.

Recent Comments